Exploring the Environmental Impact of Membrane Bioreactor in Wastewater Treatment

Exploring the Environmental Impact of Membrane Bioreactor in Wastewater Treatment

Blog Article

Understanding Membrane Bioreactors: The Future of Wastewater Therapy

Membrane bioreactors (MBRs) stand for a notable innovation in the area of wastewater therapy, integrating organic procedures with advanced membrane layer filtering to enhance effluent high quality. As global water shortage and rigid governing structures end up being progressively pressing issues, MBR innovation uses an efficient reaction through its capacity to lessen footprint and optimize source recuperation. The adoption of MBRs is not without its obstacles, which warrant mindful consideration. What are the crucial elements affecting their application and lasting practicality in various contexts? The solutions may improve our technique to wastewater management.

What Are Membrane Layer Bioreactors?

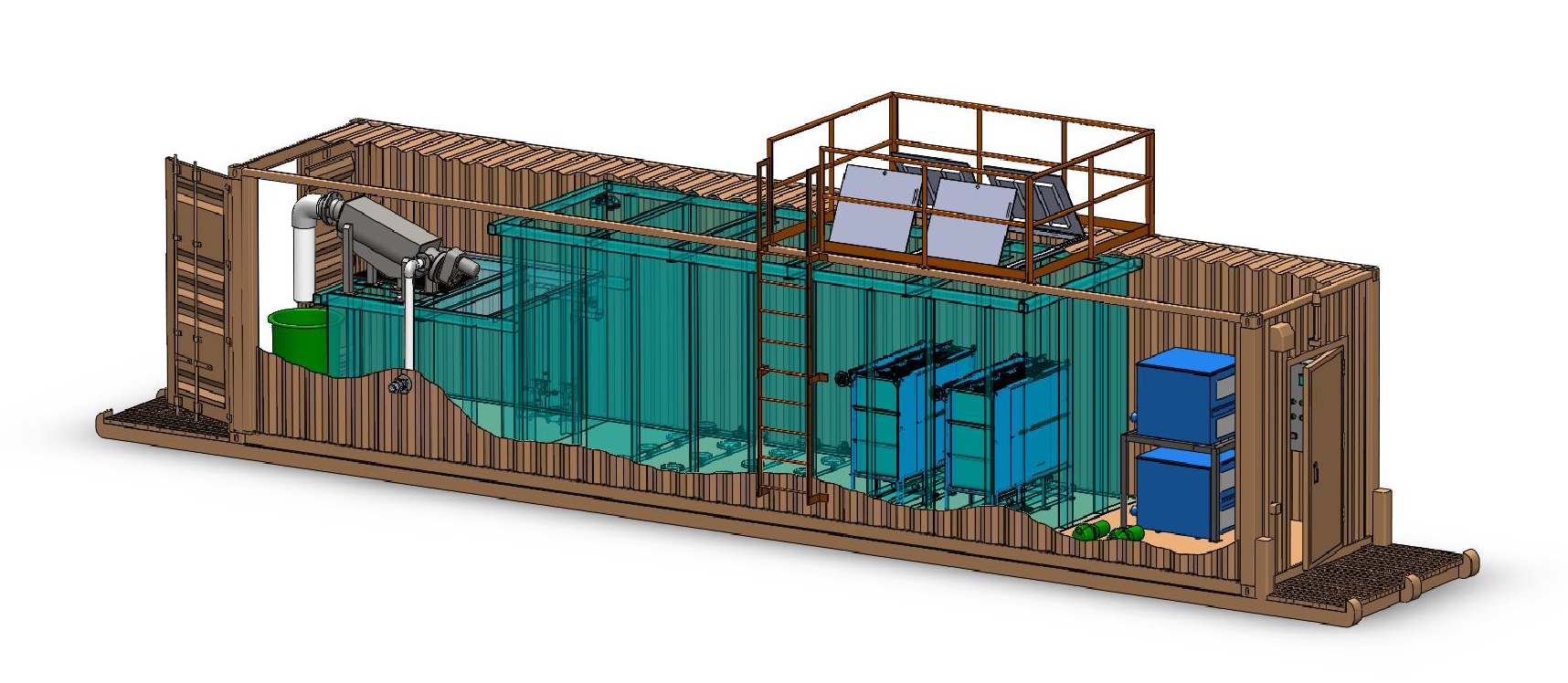

The core parts of MBR systems consist of a bioreactor where microbial activity takes place and a membrane layer unit that filterings system the combined liquor. This twin capability allows the synchronised deterioration of raw material and solid-liquid separation in a solitary step. MBRs can run in both immersed and external arrangements, with submerged systems being much more common as a result of their small design and functional efficiency.

The fostering of MBR technology has actually gained traction in numerous applications, ranging from metropolitan wastewater treatment to commercial effluent management. MBRs are specifically advantageous in situations where room is restricted or stringent effluent high quality criteria should be fulfilled. By maintaining a high concentration of microbes within the bioreactor, MBRs improve the destruction of organic toxins, thereby producing greater therapy efficiencies contrasted to typical methods.

Secret Benefits of MBR Innovation

The combination of biological treatment with membrane layer purification in MBR systems supplies numerous benefits that establish it in addition to typical wastewater therapy techniques. One of the primary advantages is the boosted effluent quality. MBRs effectively remove suspended solids and virus, attaining higher levels of filtration that fulfill rigid discharge criteria and facilitate water reuse applications.

An additional substantial benefit is the minimized sludge manufacturing. MBR systems create less excess sludge, causing reduced disposal expenses and a decrease in ecological influence. The shut nature of the membrane layer system reduces the danger of odor emissions and boosts total procedure control.

Last But Not Least, MBRs are versatile and adaptable, making them ideal for numerous wastewater kinds, consisting of commercial and community sources. The capability to integrate with advanced treatment modern technologies better boosts their performance, making MBRs an encouraging service for the future of wastewater administration.

Challenges and Limitations of MBRs

While MBR technology supplies countless benefits, it also faces numerous difficulties and restrictions that can impact its prevalent fostering. One substantial obstacle is the high funding and operational expenses connected with MBR systems. The initial financial investment for membrane products and the necessary facilities can be significant, making it much less easily accessible for smaller industries or communities.

Additionally, membrane layer fouling remains a critical concern that can decrease system efficiency and rise maintenance needs. Fouling happens when solids, natural matter, or microbes build up on the membrane layer surface, causing reduced permeability and calling for frequent cleaning or substitute.

Another restriction entails the complexity of the innovation. MBR systems call for competent employees for operation and maintenance, which can be an obstacle in areas with limited technological know-how. Furthermore, the disposal of spent membrane layers offers environmental issues, as the materials are usually not biodegradable and can contribute to lose monitoring obstacles.

Lastly, while MBRs can efficiently treat a large range of wastewater, they may not be suitable for all applications, particularly those with high concentrations of fats, oils, and greases, necessitating further research and innovation to address these limitations.

Applications of Membrane Layer Bioreactors

In numerous fields, membrane layer bioreactors (MBRs) have emerged as a flexible solution for wastewater treatment (Membrane Bioreactor). Their applications span community, industrial, and agricultural setups, showcasing their flexibility and efficiency in diverse environments. In municipal wastewater therapy plants, MBRs dramatically boost effluent high quality, enabling for water reuse and decreasing the environmental influence of released wastewater

Industrially, MBRs are employed in food and drink handling, textile production, and pharmaceutical manufacturing, where they efficiently deal get redirected here with high-strength waste streams. Their capacity to deal with rising and fall tons and varying impurity concentrations makes them specifically useful in these industries. In addition, MBRs help with the elimination of microorganisms, suspended solids, and raw material, adding to conformity with strict discharge guidelines.

In agriculture, MBRs are significantly used for treating agricultural overflow and animals wastewater, allowing the recuperation of nutrients for plant food manufacturing. They additionally aid Full Report in the therapy of greywater for irrigation, advertising sustainable water monitoring practices.

The versatility of MBRs is more evidenced by their combination with various other technologies, such as anaerobic food digestion and progressed oxidation processes, improving total performance and resource healing in wastewater treatment systems.

The Future of Wastewater Therapy

Advancements in innovation and an expanding focus on sustainability are shaping the future of wastewater treatment. Membrane layer bioreactors (MBRs) exhibit this change by integrating biological treatment processes with membrane layer filtration, causing top notch effluent ideal for reuse. The fad towards circular economies is motivating facilities to adopt MBRs for their ability to recuperate sources, such as water and nutrients, from wastewater.

Technologies in membrane layer materials and configuration are enhancing the efficiency and durability of MBR systems, minimizing functional expenses and energy consumption. Smart innovation combination, including real-time tracking and automated control systems, is additional enhancing performance and enabling predictive upkeep, hence decreasing downtime.

In addition, social assumptions and governing pressures are pushing sectors and districts to take on more sustainable techniques. Membrane Bioreactor. The change towards decentralized wastewater treatment options is acquiring grip, permitting for local therapy that minimizes transportation costs and power use

Conclusion

Membrane layer bioreactors (MBRs) stand for a transformative technique to wastewater treatment, incorporating biological processes with innovative membrane technology. The benefits of MBRs, including boosted effluent high quality, reduced spatial needs, and lower sludge manufacturing, position them as a sensible solution in the middle of expanding urbanization and stricter ecological regulations. Despite existing obstacles, the ongoing development in membrane layer materials and functional techniques assures to reinforce the efficiency and adoption of MBRs, guaranteeing their pivotal function in the future of lasting wastewater management.

Membrane layer bioreactors (MBRs) represent a notable innovation in the field of wastewater therapy, incorporating biological procedures with innovative membrane filtering to boost effluent quality.Membrane bioreactors (MBRs) incorporate organic treatment processes with membrane filtering to properly treat wastewater.The combination of organic therapy with membrane layer filtration in MBR systems provides many benefits that establish it apart from traditional wastewater treatment techniques. Membrane layer dig this bioreactors (MBRs) exhibit this change by integrating organic treatment processes with membrane filtering, resulting in high-grade effluent ideal for reuse.Membrane bioreactors (MBRs) represent a transformative approach to wastewater treatment, integrating biological processes with sophisticated membrane innovation.

Report this page